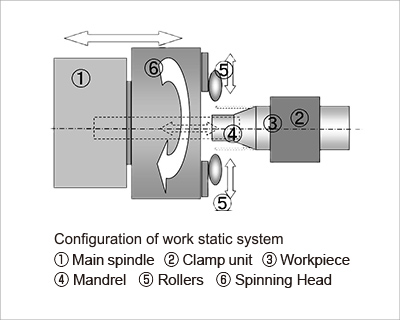

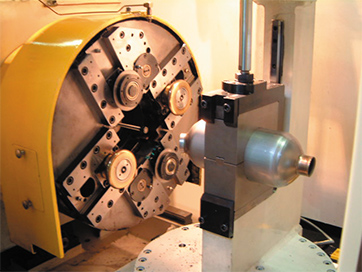

Blank tube shall be spun by rollers rotating along the tube perimeter. Compared with the conventional process (press + welding), this spinning process enables big reduction of welding process and the production cost.

Features

As this process does not need dies inside the tube, it is possible to spin the tube with brick inside

During the process, tube clamp section will not be applied with any centrifugal force as the tube does not rotate. This allows to process with a minimum clamping force, minimizing clamping scratch and possible damage on the bricks.

Because it is not necessary to stop the spindle when a tube is loaded, it makes possible to reduce the cycle time compared with work rotation method.

A wide range of options are available to meet a variety of customer needs.(An automated work loading / unloading, a work rotation, brick detection mechanism, work auto-offloading and a variable outer diameter clamp unit and so on).

The above machines are equipped with a slitter mechanism as standard, which allows a series of process from spinning to end cutting with a single chucking.

Process samples

Eccentric oblique(*)

Note: in case of processing eccentric / oblique parts, there is a possibility to infringe the third party’s patents.

For more information, please contact Nihon Spindle.

Concentric

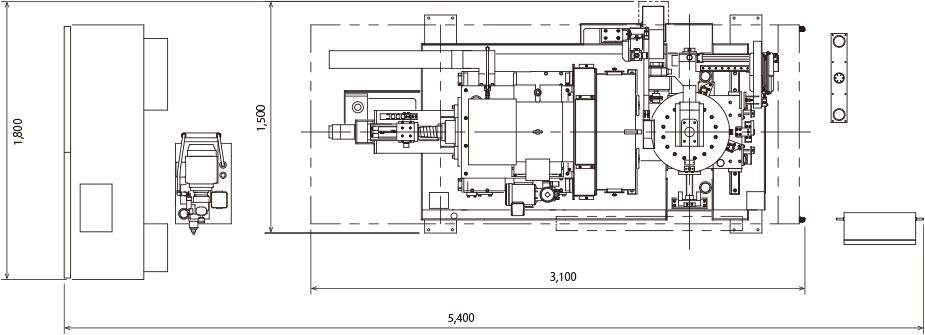

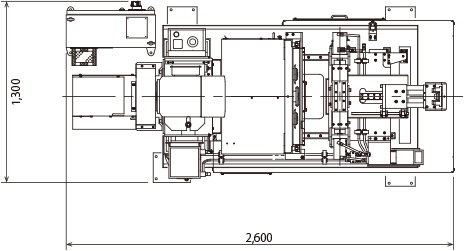

Outline Drawing

SR150-T4 / SR200-T4

SRS150-T4

Processing Area (SR150-T4)