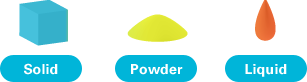

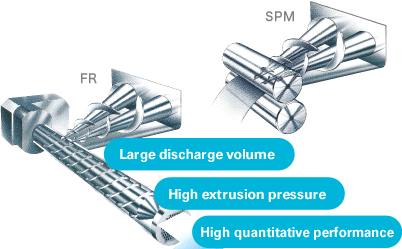

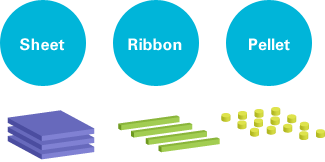

Preforming is a preliminary process done to make the material easier to process into its final shape (the shape of the finished product). Preforming processes such as straining, granulating and pellet post-processing can be made simple by attaching the proper accessory to the feeder ruder or other type of extruder in use.