Mixer

SMALL CAPACITY DISPERSION MIXER

An unsurpassed performance to meet all your mixing needs.

New composite materials are now being developed in rapid succession to meet the needs of industry. Moriyama’s dispersion mixers are specially designed for the small-batch processing required by our “new materials”era. These timely mixers meet a wide variety of contemporary mixing needs. They provide an excellent mixing performance, superb dispersion characteristics, easy handling and user-friendly controls.

Features

Though small in size, our DISPERSION MIXERs offer an number of excellent features.

-

Efficiently mixes materials in small batches. (Mixing volume capacities are available: 0.5, 1, and 3 liters/batch.)

-

Ideal for research and development of new materials and for test-mixing.

-

Exceptionally useful in small-batch production and in pilot plants.

Perfect for testing various mixing conditions. -

Facilitates production of sample materials.

Applications

Moriyama’s DISPERSION MIXERs accommodate a broad range of materials.

- Rubber compounds

By virtue of the low-temperature mixing feature, various compounding ingredients (filler) can be mixed with either natural rubber or synthetic rubber material. - Plastic compounds

Excellent for mixing calcium carbonate, talc, carbon black fillers, etc. into polymers. - Ceramics

Ideal for mixing thermoplastic resin, wax, additives, etc. with alumina and other substances. - Curing agent masterbatches

Because of the low-temperature mixing feature, a curing agent can be easily mixed with rubber or polymer. - Sealed materials for Electric-Magnetic wave

Facilitates mixing of electromagnetic-shielding metallic powder with rubber or polymer. - Plastic or rubber magnets

Excellent for mixing ferrite materials with rubber or polymer at a high filling rate. - Blending polymers

The powerful mixing performance offers good blending results with many different polymers. - Wood compounds

Wood flour or rice hull can be easily mixed with polymer.

Optional Specifications

- Dust collector

- Air compressor

- Control unit

Recorder, Programmable control unit, Spesial emergency stop device, 2-hand safety button - Jacket and piping

High-temperature type - Emergency stop unit

- Others

Products Lineup

Moriyama’s Complete Line-up Ideally Meets a Wide Variety of Needs

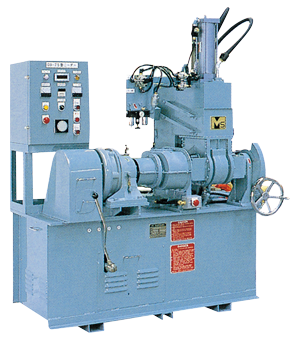

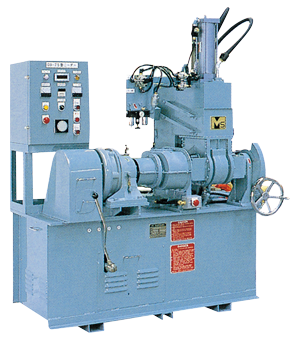

D0.5-3

Good for a expensive materials.

(The photograph shows a model equipped with an optional control panel.)Mixing volume : 0.5 liter

Motor : 3HP ( 2.2kW )

D1-5

Good for a expensive materials.

Mixing volume : 1 liter

Motor : 5HP ( 3.7kW )

Motor : 3HP ( 2.2kW )

D3-7.5

Convenient for test compounding.

Mixing volume : 3 liter

Motor : 7.5HP ( 5.5kW )

D3-10

Most popular size as a Lab mixer.

(The photograph shows a model equipped with a metal frake piping, control panel and gear box that allows the installation of a torgue meter, all of which are optionally available.)Mixing volume : 3 liter

Motor : 10HP ( 7.5kW )-

D3-20

Heavy duty for powder high loading.

(The photograph shows a model equipped with an optional control panel.)Mixing volume : 3 liter

Motor : 20HP ( 15kW )