Greetings

Greetings

Moriyama kneaders help create many familiar products available in everyday life, from the rubber found in automotive engine and components to ceramic and plastic parts of various applications. While Moriyama machines knead raw materials, each is designed to show various performance depending on materials and applications. Moriyama has accumulated the expertise needed to produce substances of widely varying viscosity, along with technological skill grounded in scientific data.

We have been working on kneading processes since our founding in 1952 (as Moriyama Works), and have continually accumulated kneading technology throughout our history. Today, Moriyama has become a well-known and respected brand not only in Japan but also around the world, earning a high degree of trust from many customers.

We will continue to further our understanding of the science behind kneading processes, and make our unflagging effort to meeting increasingly diverse market needs.

Moriyama Products

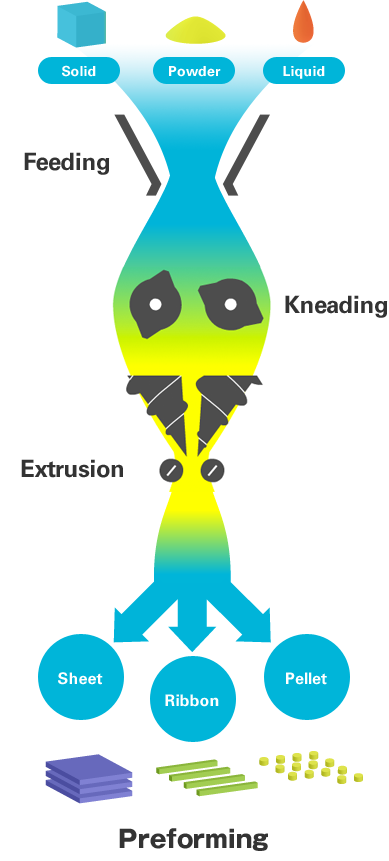

Kneading and preforming are two closely related processes vital for producing the rubber and plastic products used in everyday life. Moriyama has always been closely associated with these production processes. The kneaders and preforming extruders we manufacture are used by a wide range of manufacturing industries.

The science & technology behind kneading processes is highly subtle and complex, with results varying according to the materials and process conditions. New materials of today & tomorrow can be mixed in unlimited combination and for an endless array of applications.

To enable better extrusion-forming efficiency without sacrificing the required material performance and quality, preforming processes require the skill and expertise to satisfy a list of subtle requirements unique to each material being processed.

Moriyama’s manufacturing equipment and technology ensure that materials are processed to the required quality and performance