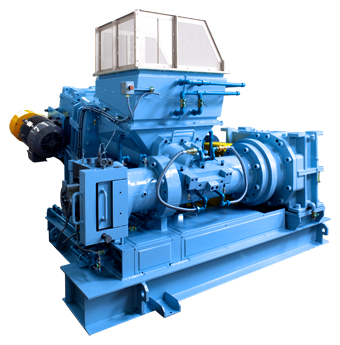

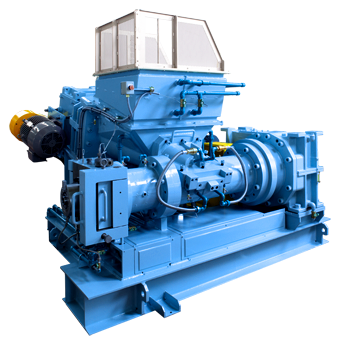

Extruder

FEEDER RUDER (FR)

The feeder ruder combines MS-type twin taper screws with a single straight screw extruder. It’s ideal for manufacturing pellets and sheets. The MS-type twin taper screws smoothly force-feed material to the single straight screw extruder. Because it allows adjustment of the extrusion pressure at higher level the FR can also strain rubber and plastics.

Features

- FR automates and reduces labor costs in pelletizing, straining and preforming processes.

- Automatic operation ensures operational safety.

- The material discharged from the mixer can be charge into FR just as it is with no further treatment.

- The MS-type twin taper screws efficiently bite and extrude the charged material.

- Easy temperature control prevents thermal deterioration of the material.

- The MS-type twin taper screws and the casing do not cotact, thus minimizing heat generation.

- The common-bed design simplifies installation.

- FR can also strain rubber and plastics.

- It’s ideal for pelletizing compound with a high filler content.

- Hot material can be fed, leading to an even greater energy savings.

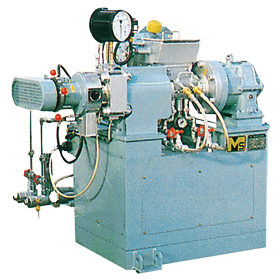

FR Type Extruder with an Innovative Vent Mechanism

The new extruder conquers the weak points associated with the conventional vent-type extruders. The simple mechanism also minimizes the cost increase of making the new extruder. The system can only be realized by Moriyama’s unique structure, a feeder ruder (FR) type extruder that combines a twin tapered screw extruder (feeder) and a single straight screw extruder (ruder).

Main features

- Unlike the conventional extruder in which the vent port is located on the flow of material, the system is de-aerated by drawing air at the sealed section where the feeder joins the ruder. The vent port is located in the upper stream to prevent from vent up.

- The extrusion rate remains at a given level as the structure of the single straight screw extruder does not require a special design as in the conventional extruder in which the output will decrease with the change in the vent screw design.

- The new design contributes to cost reduction as it does not require the complex shape and large L/D that are normally required of the vent screw.

The vent mechanism is fitted to the FR-65 in our testing plant. You are welcome to verify the effect of the invention using your material.

Feeder Ruder with Vent mechanism(FR)

Eliminate porous from inside of material

Eliminate porous from inside of material

Lower water content inside of material

Features

- No vent up

Normally vent zone is designed on the barrel where material flows however, our design is to make vent hole oppposite side of flow which contribute no vent up. - Applicable for various kind of materials

Simple screw design, small L/D, speed adjustable individually for Feeder and Ruder that enables to fit a various kind of recipe - Small initial cost

Small L/D requires no big initial cost

[SBR+Calcium carbonate]

No Vent port

Cross section picuture of extruded

material(x10)

With Vent port

Cross section picuture of extruded

material(x10)

Vent mechanism is applied on our Test Lab., FR-65 in our Test facility. You can confirm Vent performance with your materials.

Optional Specifications

- Feeder section

Jacket structure of hopper, - Ruder section

L/D(4,8 and 10) - Head section

Hydraulic clamper, Double heads, Thermometer for compound, Screen pack, Automatic screenchanger - Cutter (pelletizer) section

Dusting equipment, Cooling jacket for cutter hood - Temperature control

Hot water unit, Heat medium unit, Chiller unit, Casting heater (for cylinder), Temperature controlling motor valve - Accessories

Cyclone, Pellet cooler (rotary drum), Vibrating sieve, Pellet de-watering machine and hot water circulator, Spot cooler, Recorder - Others

Structure

- The FR is composed of a feeder section featuring MS-type twin taper screws and a single straight screw extruder.

- The feeder section efficiently bites charged material and ensures effective cooling.

- Because the MS-type twin taper screws and the single straight screw are driven by different motors, their speeds can be independently adjusted.

- The intermediate section connecting the feeder and ruder sections can be opened for easy cleaning.

- The head section may be equipped with a screen pack or an automatic screen changer.

Specification

| Model | FR35 | FR65 | FR75 | FR100 | FR125 | FR150 | FR180 | FR200 | FR250 |

|---|---|---|---|---|---|---|---|---|---|

| Corresponding Mixer Size ( liter ) *1 |

3 | 10 | 20 | 55 | 55 | 75 | 110 | 150 | 200 |

| Output ( l/H ) *2 |

20 | 100 | 135 | 250 | 390 | 600 | 740 | 1000 | 1500 |

| Feeder section ( MS-type Twin Taper Screw ) | |||||||||

| Screw Revolution ( rpm. ) |

2.6~26 | 2.0~20 | 2.0~20 | 2.0~20 | 2.0~20 | 1.3~13 | 1.3~13 | 1.3~13 | 1.5~15 |

| Motor ( kW ) |

0.75 | 2.2 | 3.7 | 5.5 | 11 | 11 | 15 | 22 | 30 |

| Ruder section Single Straight Screw Extruder | |||||||||

| Screw dia. ( mm ) |

35 | 65 | 75 | 100 | 125 | 150 | 180 | 200 | 250 |

| L/D | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Screw Revolution ( rpm. ) |

12~120 | 9.5~95 | 8.0~80 | 7.5~75 | 6.0~60 | 5.2~52 | 4.5~45 | 4.0~40 | 3.5~35 |

| Motor ( kW ) |

2.2 | 7.5 | 15 | 22 | 37 | 55 | 75 | 90 | 90 |

| Cutter ( Pelletizer ) section *3 | |||||||||

| Cutter motor ( kW ) |

0.4 | 0.75 | 1.5 | 1.5 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 |

| Pellet discharge blower ( kW ) |

0.4 | 0.75 | 1.5 | 1.5 | 2.2 | 3.7 | 3.7 | 3.7 | 3.7 |

* Specifications, external appearance are subject to change without prior notice

*1: Also applicable to combine with Internal Mixer, Open-Type Mixer

*2: Output depends on formulations

*3: Die face hot cut pelletizer in the air

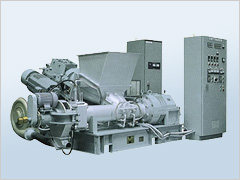

Products Lineup

FR35

With hot face cut pelletizer

FR65

With underwater pelletizer

FR125

With a roiler die

-

FR150

With a reduced L/D for rubber compounds

With hot face cut pelletizer -

FR200

-

FR250

With hot face cut pelletizer