Products

High speed rotor will generate mechanical shear and cavitation. Cavitation will contribute to disperse agglomerates by expansion and shrinkage of microbubbles. Also applicable for dispersion of CNF (Nano Cellulose Fiber ) in a short time with mildly and uniformly.

Catalog download [PDF]

Features

- Liquid, powders will be available for continuous supply、dissolving and dispersion

- Realize 5~6 times in productivity compare to conventional mixers

- Realize to minimize process due to several kinds of powders can be fed in one time

- Compact design allows to space-saving

- All parts can be completely dismantled which meets sanitary requirement

Applications

- Battery

- Lithium Ion Batteries, Capacitors, Fuel Cell, Binders

- Medicine

- Medical patch, Ointment

- Chemicals

- High molecular composite, Toner, Coating agents

- CNF(Cellulose Nano Fiber)

- Cosmetics

- Emulsion, Sun screen cream

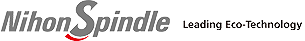

General examples in capability for dispersion & dissolving

Advantages of JET PASTER

- How to make a Electrode slurry by JET PASTER

- Quick & mild dispersion Making use of Microbubbles generated by cavitation

- Dispersion stability of Inorganic composite available by CNF

Cavitation bubble plasma processing device

- Application of cavitation bubble plasma

- Plasma is generated by applying high voltage to cavitation bubbles

Applicable for dispersion, Nanoparticle synthesis, Sterilization. High speed, bulky treatment will be available so,a novel technology to be applied to industrial requirement - > more

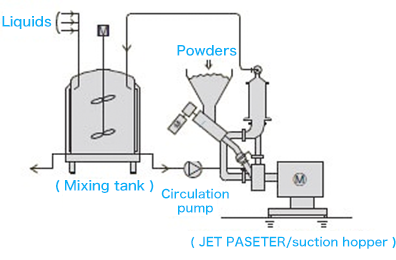

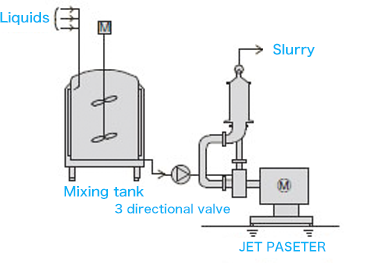

System integration

- Circulation system

- For deep dissolving, high dispersion case

- Improve current process / use final dispersion

- Position JET PASTER after current mixer to shorten cycle time and acquire better dispersion

Series of our product

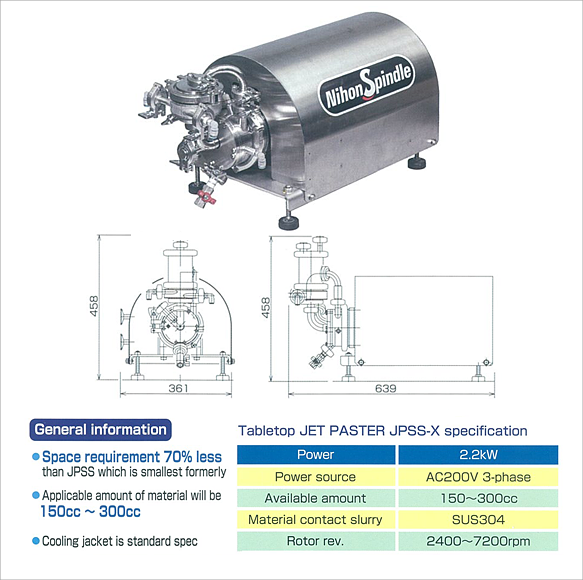

- JPSS-X

- for Laboratory purpose

- JP-L

- Realize high productivity due to high speed dispersion

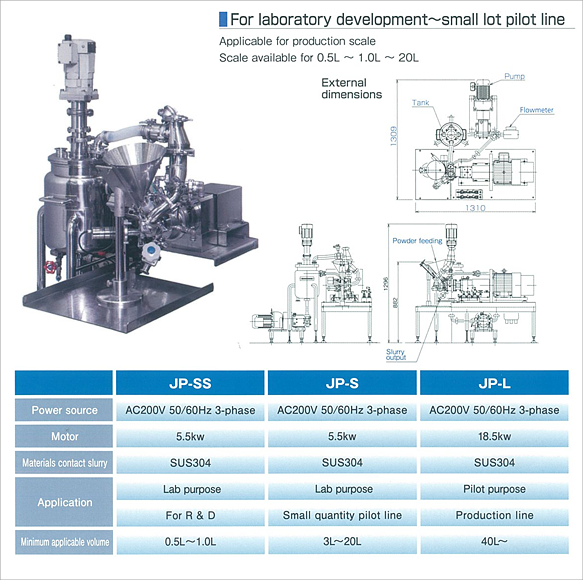

- JP-SS ~ JP-S

- for Laboratory development~small lot pilot line

- Techno-stage

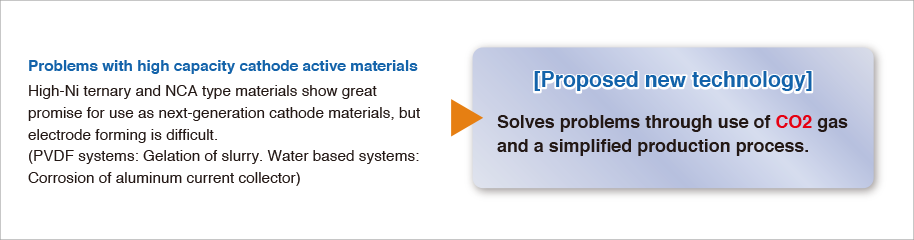

Cathode manufacturing method using water process

New technology solves problems with high capacity cathode active materials