Technology of Nihon Spindle

Introduction of R&D test center and R&D test machines

A variety of R&D machines for each customer's product are on standby in R&D center in order to consider introducing Nihon Spindle machine.

R&D center is a space that is not only verifying performance of machine but also connecting customer and Nihon Spindle by joint development with customers

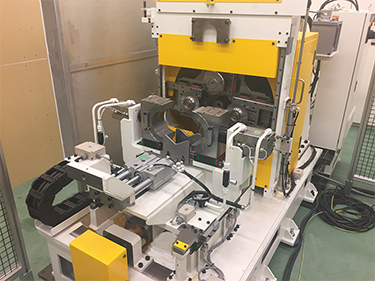

FFC (Flow Forming Center)

To meet various customer’s requests such as “want to switch into spinning process” or “can you make a shape like this?,” a variety of R&D machines are on standby in Nihon Spindle’s Flow Forming Center (FFC). FFC is ready for prototyping or joint development with customers as well as development of own original technology.Please feel free to contact us.

- R&D spinning machine for small products

- R&D spinning machine for large products

- R&D spinning machine for exhaust parts (concentric/eccentric/oblique process)

- R&D Vertical flow forming machine

- R&D spinning machine for exhaust part (concentric process only)

- R&D high-speed spinning machine

- R&D High power flow forming machine

Techno-stage (MS/Moriyama)

Technostage is our test facility that is for the right evaluation of our machine qualities. Customers can do trials by using their own material for the right selection that can fit in to customers’ requirement.

We own various kind of machines that can meet customers’ requirements.

In addition to test machines, we also have a measuring instrument for evaluating the kneaded material and a microscope for observing the condition of the material.

Our equipment

- 【Kneaders】

8 kneaders from 0.5L to 55L. … Meet a wide range of kneading needs, including new materials such as high-hardness rubber, plastic, and ceramics. - 【Extruders】

5 extruders including SPM that can be used for straining ... The material discharged from a kneader can be directly inserted to a high-performance extruder. - 【Others】

Mooney viscometer, rubber cutting machine, etc.

Actual test examples

We are an experienced expert of mixing and extrusion for various industries. Please do not give up on difficult-to-mix and high-hardness materials.。

- Test example with Wonder Kneader

Verification of dispensability of FKM and pigment

Verification of cooling kneading containing vulcanizing material

Verification of shortening of mixing time for high-hardness rubber and powder - Example of implementation at KR (Kneader Ruder)

Verification of discharge of highly adhesive materials

Verification of the degree of deforming in vacuum kneading

- Test example with 2TR / FR

Verification of rubber storage on high mesh (# 400 and above)

Verification of extrusion mold ability of rice flour for food industries

Verification of extrusion processing amount of cellulose material - Test examples with SPM

Verification of mold ability and processing amount to realize roll less line

Verification of mold ability of thin sheet (t1 ~ 2mm)

-

55L Kneader Line(55L Kneader, Bucket conveyor, Sheet preforming machine)

-

10L Kneader, Sheet preforming machine

-

1L Kneader, 3L Kneader

Techno-stage (Jet paster)

We have JPSS-X for research, JPSS & JPS for development & pilot, and JPL for production, and we can test according to customer needs.

We have also developed a water-based slurrying of high-capacity positive electrode active materials for lithium-ion batteries. You can try our new technique at our Lab(Techno-Stage),

We have various measuring devices such as rheometers, B-type viscometers, microscopes, grind gauges, and solid content measuring device to be evaluated on our Techno-Stage.

Line-Up of our devices

- "Jet paster" JPSS-X, JPSS, JPS, JPL

| JPSSX | : | You can make slurry preparation trials with a small amount of 150 to 300 ml. It is possible to make many trials a day by chenging slurry's composition and triall conditions. It is suitable for making many CR2032 batteries to evaluate cycle characteristics, high temperature and low temperature characteristics so on. |

| JPSS,JPS | : | A slurry of about 1L to 10L can be produced. Continuous coating traials with a coater. This scale is ideal for large batteries produceded in the laboratory. It can also be used for samples. |

| JPL | : | It is a device for mass production. We can handle from 40L / B to several hundreds of L / B. A large amount of slurry that requires soft dispersion can be produced in a short time. It boasts more than five times the productivity of planetary mixers. |

Number of traials per year

- We carry out about 60 tests a year from Japan and overseas.。

-

JPSS-X For Laboratory(0.15~0.3L/B)

-

JPSS & S For R&D & Small quantity pilot line(1L~5L/B)

-

JPL Production line(40L~500L/B)