Extruder

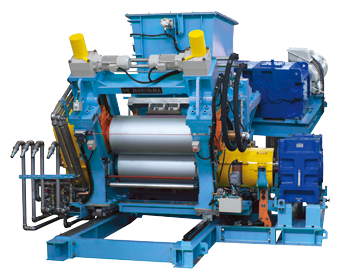

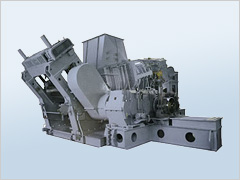

SHEET PREFORMING MACHINE (SPM)

The Sheet Preforming Machine is an extruder that combines MS-type twin taper screws with a roller head, making it ideal for the manufacture of preformed sheets and slab sheets. Material is cooled by both the MS-type twin taper screws and the roller head, providing an excellent cooling effect for materials which can be damaged by heat such as rubber compounds.

The superb cooling effect is perfect for compounds containing vulcanizing agents as well as final batches. It’s also effective in preventing scorching.

The Features of new SPM (Semi-Open)

-

A substantial energy conservation is possible

-

Quality and performance is constantly secured on each batch of production

-

Free from damage risk to the roll

-

Easy and smooth operation with compression lid

-

A lot of space saving possible

-

Automation of the sheeting process helps reduce labor costs.

-

Automatic operation improves operational safety.

-

It’s possible to charge material coming from the mixer as it is without treatment.

-

The MS-type twin taper screws smoothly bite and extrude the charged material.

-

The superb cooling effect prevents scorching during final mixing when blending vulcanizing agents.

-

The MS-type twin taper screws and the casing do not contact, thereby reducing heat generation.

-

The screw and roller revolutions can be automatically controlled by installing a bank controller with compression lid.

-

The self-cleaning screws leave almost no residual material in the casing.

-

The common-bed design of most models facilitates installation.

-

Hot material can be fed, thus further reducing energy costs.

-

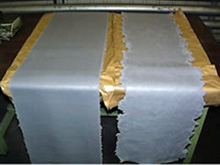

Clean sheet edge available

< Comparison of sheet edge shape

< Comparison of sheet edge shape

(Compound : Silica rubber compound)

Right : Conventional type

Left : SPM-SO

No material to remain in the bank.

Applications

- Sheeting of rubber compounds

- Sheeting of plastic compounds

- Others

Optional Specifications

- Feeder section

Jacket structure of hopper, Hopper cover, Hopper level sensor - Roller head section

Motor-driven lift of top roll (SPM 200 and largest-capacity models are equipped with this lift as standard), Emergency brake for rolls, Type with different speeds between top and bottom rolls (friction type), Bank controller - Temperature control

Hot water unit, Heat medium unit, Chiller unit, Temperature controlling motr valve - Others

Structure

- The SPM consists of a feeder section featuring MS-type twin taper screws and a roller head section in which two rolls are vertically arranged.

- The feeder section efficiently bites charged material and provides an excellent cooling effect.

- The MS-type twin taper screws and the two rolls are driven by different motors, allowing their speeds to be independently adjusted.

- A bank controller can be installed between the feeder and the roller head section to permit automatic speed adjustment or the MS-type twin taper screws and the rolls.

Structural view of SPM

Specification

| Model | SPM20 | SPM75 | SPM75-SO | SPM110 | SPM200 | SPM300 | SPM6NS | SPM6NH |

|---|---|---|---|---|---|---|---|---|

| Corresponding Mixer Size | ||||||||

| DISPERSION MIXER ( liter ) |

10/20 | 35/55/75 | 35/55/75 | 110 | 150/200 | 300 | - | - |

| Internal mixer ( liter ) |

- | 70 | 70 | 80 | 120 | 120 | 240 | 240 |

| Max. output ( l/H ) *1 |

200 | 700 | 700 | 1200 | 2000 | 3300 | 5000 | 6000 |

| Feeder section | ||||||||

| Mortor ( kW ) |

5.5 | 15 | 7.5 | 22 | 37 | 45 | 75 | 90 |

| Roller head section | ||||||||

| Mortor ( kW ) |

3.7 | 7.5 | 7.5 | 15 | 22 | 37 | 55 | 75 |

| Roll diameter ( mm ) |

230 | 348 | 200 | 400 | 468 | 500 | 500 | 500 |

| Roll width ( mm ) |

350 | 600 | 600 | 600 | 700 | 800 | 900 | 900 |

| Roll gap ( mm ) |

2~5 | 3~6 | 3〜6 | 4~8 | 4~8 | 4~8 | 4~8 | 4~8 |

| Sheet width available ( mm ) |

250 | 500 | 500 | 500 | 600 | 700 | 750 | 750 |

| Model | SPM9NS | SPM9NH | SPM9NH-SO | SPM12NS | SPM12NH | SPM12NH-SO |

|---|---|---|---|---|---|---|

| Corresponding Mixer Size | ||||||

| DISPERSION MIXER ( liter ) |

- | - | - | - | - | - |

| Internal mixer ( liter ) |

270 | 270 | 270 | 370 | 370 | 370 |

| Max. output ( l/H ) *1 |

7000 | 9000 | 9000 | 9000 | 12000 | 12000 |

| Feeder section | ||||||

| Mortor ( kW ) |

90 | 110 | 110 | 110 | 132 | 132 |

| Roller head section | ||||||

| Mortor ( kW ) |

90 | 110 | 90 | 132 | 160 | 132 |

| Roll diameter ( mm ) |

600 | 600 | 420 | 700 | 700 | 480 |

| Roll width ( mm ) |

1000 | 1000 | 1000 | 1050 | 1050 | 1050 |

| Roll gap ( mm ) |

4~8 | 4~8 | 4〜8 | 4~8 | 4~8 | 4〜8 |

| Sheet width available ( mm ) |

850 | 850 | 850 | 900 | 900 | 900 |

| Model | SPM19NS | SPM19NH | SPM30NH | SPM30NH-SO |

|---|---|---|---|---|

| Corresponding Mixer Size | ||||

| DISPERSION MIXER ( liter ) |

- | - | - | - |

| Internal mixer ( liter ) |

370 | 370 | 620 | 620 |

| Max. output ( l/H ) *1 |

14000 | 19000 | 30000 | 30000 |

| Feeder section | ||||

| Mortor ( kW ) |

200 | 250 | 300 | 300 |

| Roller head section | ||||

| Mortor ( kW ) |

220 | 300 | 450 | 450 |

| Roll diameter ( mm ) |

850 | 850 | 850 | 700 |

| Roll width ( mm ) |

1200 | 1200 | 1500 | 1500 |

| Roll gap ( mm ) |

4~8 | 4~8 | 5~10 | 5〜10 |

| Sheet width available ( mm ) |

1050 | 1050 | 1350 | 1350 |

* Specifications, external appearance are subject to change without prior notice

*1:Output depends on formulations

Products Lineup

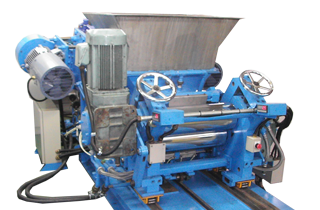

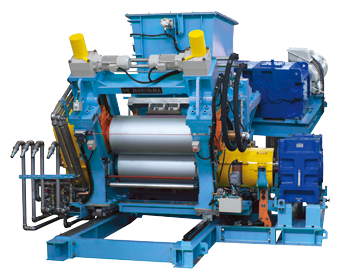

SPM75

For use with 75 l/batch capacity DISPERSION MIXER.

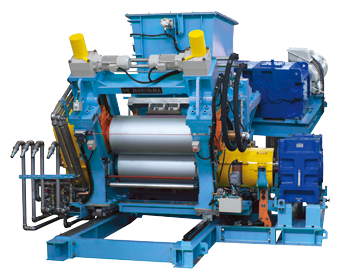

SPM75-SO

New SPM with a bank controller, compression lid, enables a stable yet smooth material flow, resulting in a substantial energy conservation.

For use with 75 l/batch capacity DISPERSION MIXER.

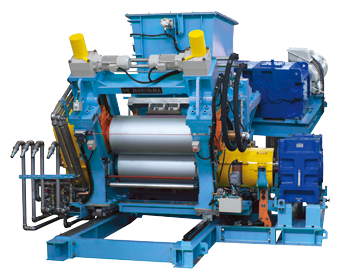

SPM110

For use with 110 l/batch capacity DISPERSION MIXER.

SPM9NH-SO

New SPM with a bank controller, compression lid, enables a stable yet smooth material flow, resulting in a substantial energy conservation.

For use with 270 l/batch capacity DISPERSION MIXER.

SPM12NS/H

For use with 370 l/batch capacity internal mixer.

SPM12NH-SO

New SPM with a bank controller, compression lid, enables a stable yet smooth material flow, resulting in a substantial energy conservation.

For use with 370 l/batch capacity DISPERSION MIXER.

-

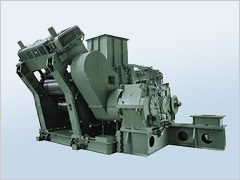

SPM19NS/H

For use with 370 and more l/batch capacity internal mixer.

-

SPM30NS/H

For use with 620 l/batch capacity internal mixer.

SPM30NH-SO

New SPM with a bank controller, compression lid, enables a stable yet smooth material flow, resulting in a substantial energy conservation.

For use with 620 l/batch capacity DISPERSION MIXER.