Products

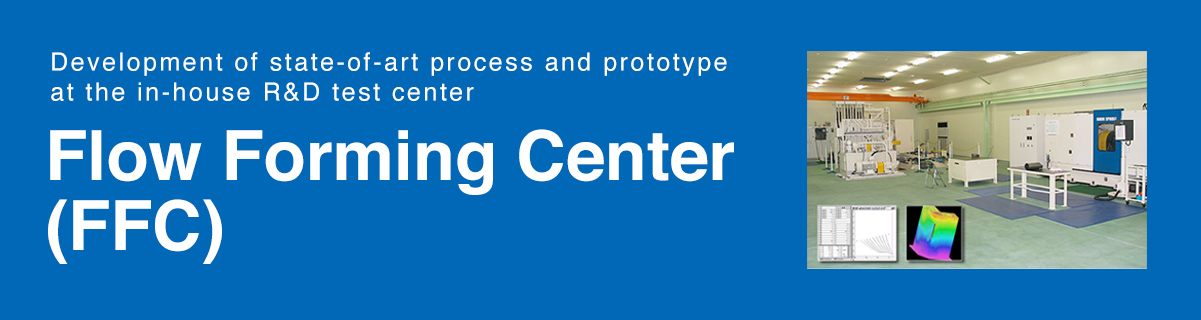

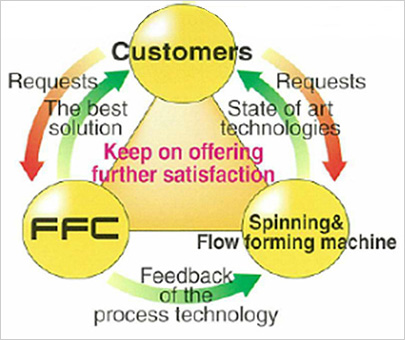

To meet various customer's requests such as "want to switch into spinning process" or "can you make a shape like this?," a variety of R&D machines are on standby in Nihon Spindle's Flow Forming Center (FFC). FFC is ready for prototyping or joint development with customers as well as development of own original technology.

Consultation about parts shape

(from customer)

Advice on process engineering

Experienced staff helps you develop flow forming process design (shapes proposal, cost reduction).

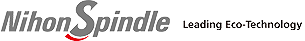

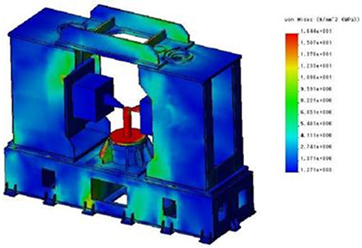

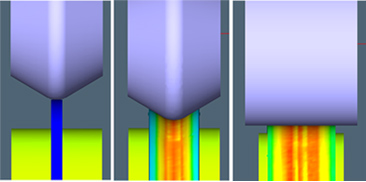

Simulation technologies is available

-

Upper & lower process after cleavage

-

Analysis sample

Virtual process verifying by simulation technology is available

Spinning trial/ prototyping

Trial shall be made by the most suitable machine for each application from a wide selection of R&D machines.

Remote test trial is available/ Forming process is visible by web camera

・Variety of measuring device is available

(Measuring shape of sample and Measuring sample by coordinate measuring machine)

・Know-how by Leifeld Metal Spinning as pioneer of forming process is available

-

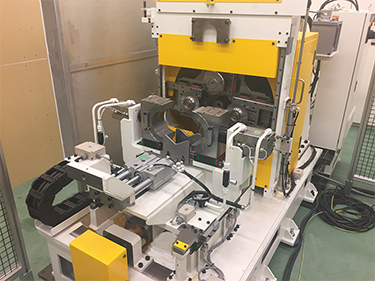

Inside of Flow forming center

-

The image of remote test trial

(Video shall be taken inside of R&D test machine) -

Coordinate Measuring Machine

Parts evaluation (by customer)

Proposal for the production machine

Proposal for the production machine is based on the data obtained through the trial and prototype.

Nihon Spindle proposes optimal production machine which is based on the thrust data obtained through actual trial.

Machine design & manufacturing

- Delivery and installation

Nihon Spindle provides machine installation service as well as after-service both in Japan and overseas.

-

-

<Reference processable area>

Material diameter:φ30~φ1,500

Thickness:0.5㎜~15㎜

Material:S45C,SPHC,SUS304,SUS409,

Alunimum,Titanium.Magnesium,Niobium*Depending on the shape of material , processable area shall be variable.

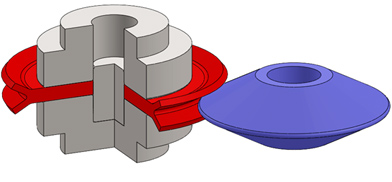

R&D Machines

- R&D spinning machine for small products

- Faced type roller base allows spinning with up to five tools.

- R&D spinning machine for large products

- Machine for large products with a maximum material outer diameter of 1500 mm.

- R&D spinning machine for exhaust parts

(concentric/eccentric/oblique process) - Dedicated pipe end compression machine. It is even possible for eccentric and oblique spinning. The machine is applied for the fixed workpiece method.

- Vertical flow forming machine

- Flow forming machine with electric servo for high-precision machining. Also suitable for forged / cast aluminum wheel flow forming and flow forming of transmission parts.

- R&D spinning machine for exhaust part

(straight process only) - R&D machine specially designed for catalyst case and muffler. It is applied for the fixed workpiece method.

- R&D high-speed spinning machine

- Fully electric R&D machine capable of high-speed spinning up to a maximum spindle rotation speed of 3000 rpm.

- Horizontal high-power flow forming machine

- High-rigidity model for flow-forming processing equipment that enables thick-plate forming. Faced type roller base allows machining with up to eight tools.