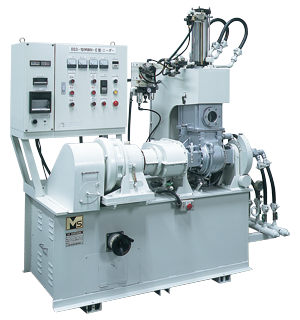

Mixer

REDUCED PRESSURE DISPERSION MIXER

Eliminate porous inside of the materials for DPF, Ceramic honey-come extrusion

The pressure-reducing DISPERSION MIXER is a new product developed to mix ingredients for new materials and highly rigid rubber compounding materials at reduced pressure. Because materials are mixed at reduced pressure, far fewer bubbles are generated in them, and many other advantages are obtained. This new DISPERSION MIXER is ideal for high-quality compounding.

Features

-

Far fewer bubbles are generated in the material mixed.

-

Powerful mixing is performed by pressurization at reduced pressure.

-

Highly rigid rubber compounds and other hard-to-mix materials can be mixed easily.

-

Advantages of mixing at reduced pressure are obtained, including improved properties.

Applications

- The mixer can accommodate a variety of materials for the production of rubber compounds, plastic compounds, ceramic compounds, new materials, and adhesives.

Specification

| Model | DV3-10 |

|---|---|

| Mixing capacity ( liter ) | 3 |

| Rotor speed ( rpm. ) | Front : 3.2~48 Rear : 2.6~39 |

| Motor capacity ( kW ) | 7.5 variable speed motor |

| Inversion method | Electric inversion 0.4kw |

| Vacuum Pump ( kW ) | 0.4 |

* Other model besides DV3-10 is available upon request.

* Specifications and external view are subject to change without prior notice for improvement.