Mixers

DISPERSION MIXER

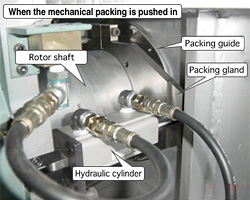

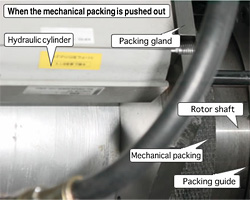

Mechanical Seal Quick Maintenance System

In pursuit of the ease of maintenance

A mechanical packing is used to seal the Mixer shafts. In the standard system, a spring is flexed to push the spring against the sliding surface by way of the packing gland in order to gain the necessary surface pressure in the seal.

Replacement or cleaning of the mechanical packing is not an easy work as the packing gland and guide must be removed before the packing can be removed for replacement or cleaning. After the new or cleaned packing is installed, the spring must be flexed to the necessary dimension.

A new system using a hydraulic cylinder has been invented to reduce the work time and thus improve the ease of maintenance. The packing is detached and attached and the necessary sealing pressure is obtained by means of the hydraulic cylinder rather than the spring.

Main features of the Mechanical Seal Quick Maintenance System

- The use of the hydraulic cylinder ensures faster detaching and attaching for a greater ease of replacement and cleaning of the packing.

- The surface pressure of the packing can be altered easily by adjusting the hydraulic pressure.

- The system structure allows retention of the hydraulic pressure. Once the necessary pressure is reached, the hydraulic pump can be turned off to eliminate the loss of energy.

- The entire system is designed in such a way the surface deflection of the sliding surface, thermal expansion of the shaft, rattling of the bearing, etc., are absorbed during the sliding operation. This ensures a high stability of the surface pressure.